Your Bolt flange torque pattern images are available. Bolt flange torque pattern are a topic that is being searched for and liked by netizens today. You can Download the Bolt flange torque pattern files here. Find and Download all royalty-free photos.

If you’re searching for bolt flange torque pattern pictures information connected with to the bolt flange torque pattern topic, you have visit the right site. Our website always gives you suggestions for refferencing the maximum quality video and image content, please kindly surf and find more informative video content and images that match your interests.

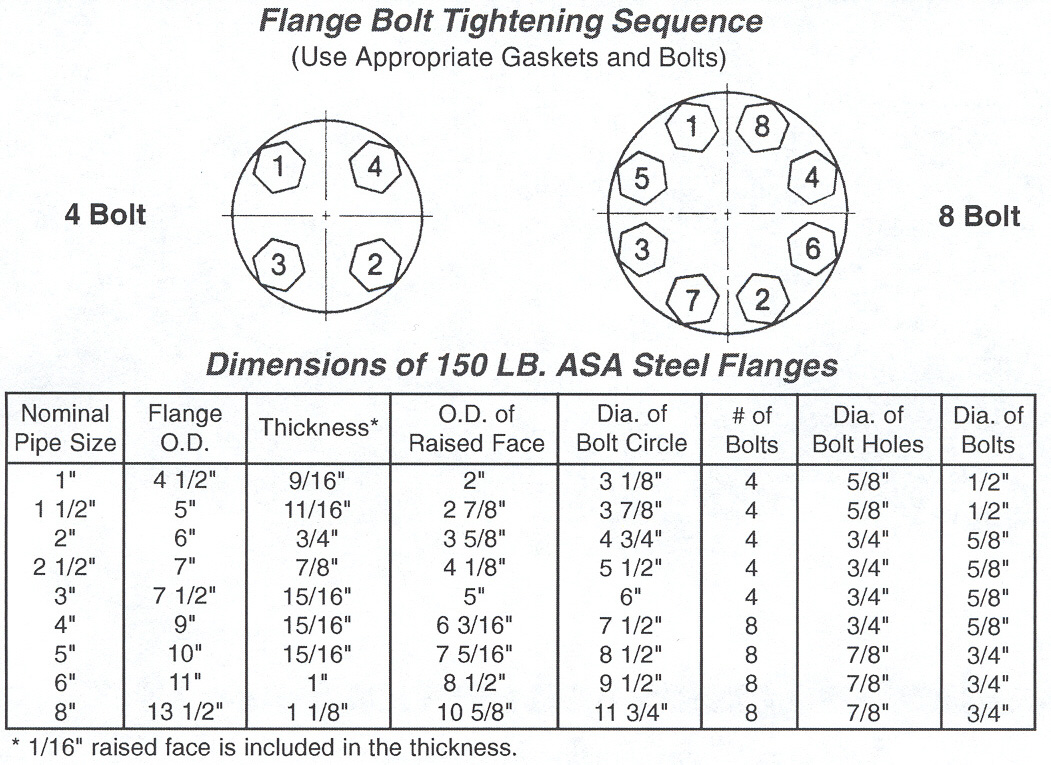

Bolt Flange Torque Pattern. Diameter of studs 3. Bolt Tightening Sequence to Follow. HYTORC offers the latest hydraulic bolting technology with unique patented benefits that provide industry-leading safety and accuracy. Welcome to this interactive flange bolting calculator from HYTORCThe program computes recommended torque values bolting patterns tool selection and pump pressure settings for standard ASME B165 and API 6A flanges under normal assembly conditions.

8 Bolt Torque Pattern Flange Bolt Chart From flangeboltchart.com

8 Bolt Torque Pattern Flange Bolt Chart From flangeboltchart.com

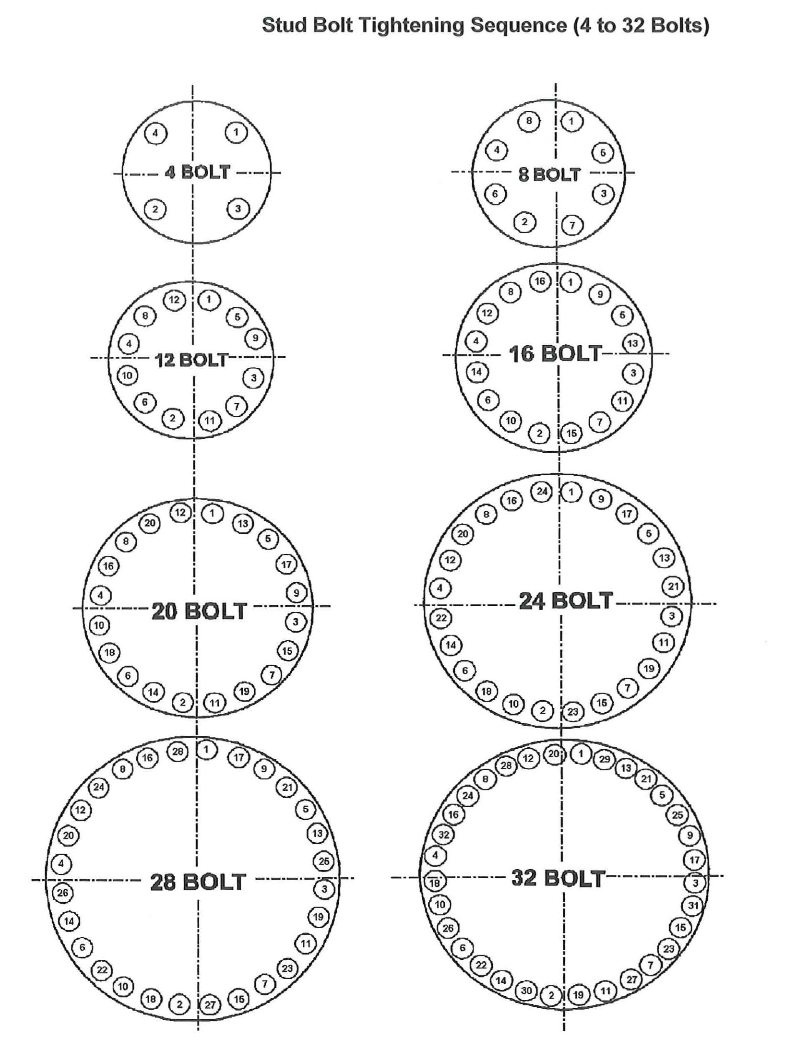

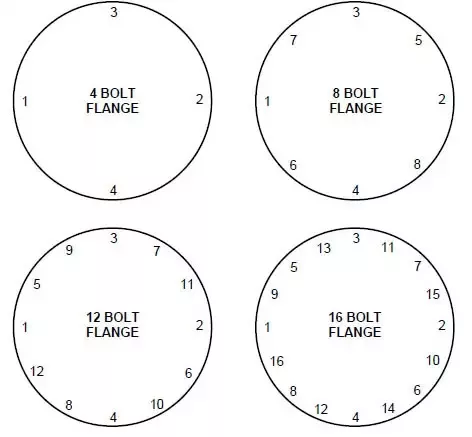

Torque pattern for 36 bolt flanges. The guide includes the tightening pattern for 16 20 24 28 32 36 40 44 48 52 60 76 and 96 bolts. Number bolts in cross-pattern sequence according to the appropriate sketch below. Lookup flange bolt torque patterns on your phone in seconds. Torque pattern for 16 bolt flanges. And CFOs loathe over paying for tools.

Then SNUG BOLTS UP to 1020 FT-LBS torque but DO NOT EXCEED 20 of target torque.

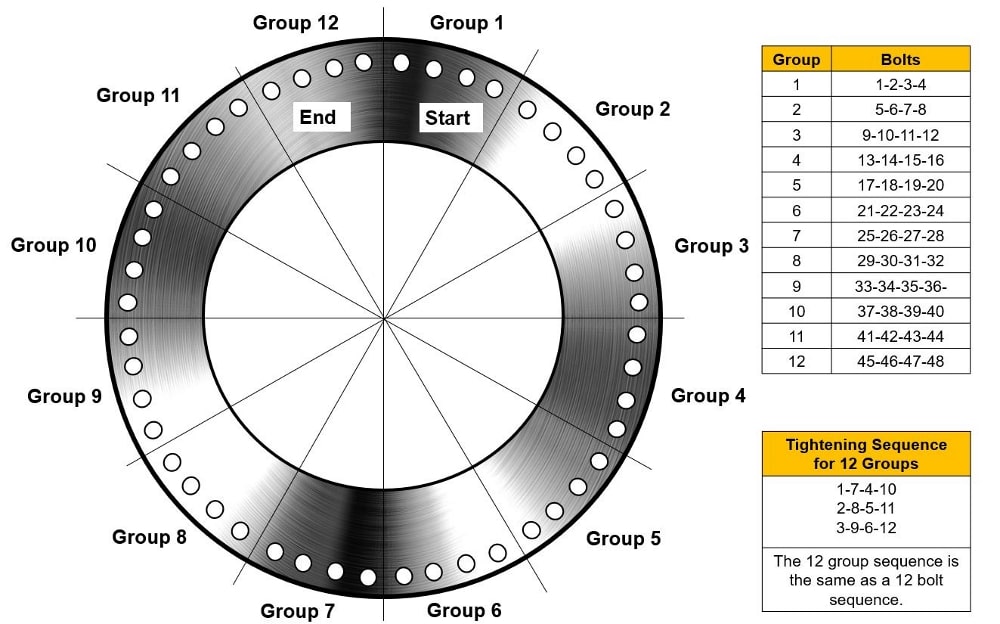

Starting at the 1 bolt use the appropriate cross-pattern tightening sequence in the sketch below for. HYTORC offers the latest hydraulic bolting technology with unique patented benefits that provide industry-leading safety and accuracy. Garlock SEALING TECHNOLOGIES an EnPro Industries company. For easy handling bolt numbering shall be done clockwise around the flange with the following sequence. 14 4 48-Bolt Flange Bolt Grouping Example. Texas Flange has been in the business of prec.

Source: uipintl.com

Source: uipintl.com

Based on using weldneck flanges lubricated stud bolts with a 015 friction factor ansi 900 flange ansi 1500 flange ansi 2500 flange rec. And CFOs loathe over paying for tools. Look up flange bolt sizes and torque patterns in three taps with Flange Bolt. Even though flange blot toque calculation is possible they are normally selected from the pipe flange bolt torque chart. Even those adept at math dislike having to calculate the proper pattern for bolts greater than 8 sequences.

Source: blog.enerpac.com

Source: blog.enerpac.com

The first thing you do is tighten each flange bolt between 20 and 30 of your target ft-lbs in the star pattern. 7 3 Recommended Tool Tightening Method and Load-Control Technique. Lookup flange bolt torque patterns on your phone in seconds. Torque pattern for 36 bolt flanges. Garlock SEALING TECHNOLOGIES an EnPro Industries company.

Source: flangeboltchart.com

Source: flangeboltchart.com

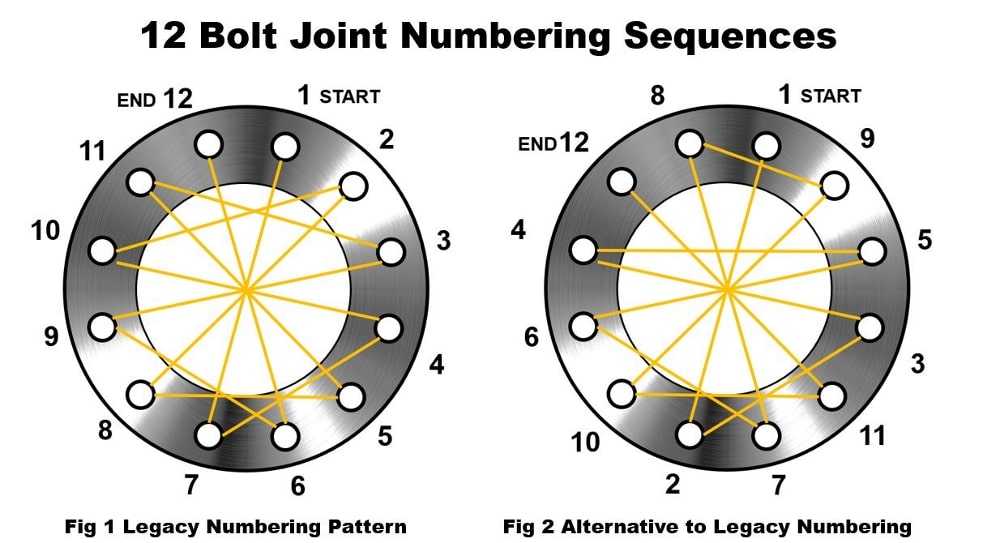

Then SNUG BOLTS UP to 1020 FT-LBS torque but DO NOT EXCEED 20 of target torque. Set the torque wrench to 100 torque value and repeat crisscross pattern for a 4th time. 14 4 48-Bolt Flange Bolt Grouping Example. 3 Example Legacy Pattern 12-Bolt Tightening Sequence. Number of Bolt Stud.

Source: chiefdelphi.com

Source: chiefdelphi.com

Number bolts in cross-pattern sequence according to the appropriate sketch below. Starting at the 1 bolt use the appropriate cross-pattern tightening sequence in the sketch below for. 7 4 Legacy Cross-Pattern Tightening Sequence and Bolt-Numbering System. Look up flange bolt sizes and torque patterns in three taps with Flange Bolt. The pattern itself is to apply to bolts 1-4 below in orderthen move to bolts 5-8 again applying torque in orderand.

Source: flangeboltchart.com

Source: flangeboltchart.com

3355 psi hydro test pressure. Instant flange bolt sizes and torque patterns. Length of studs 4. Lookup flange bolt torque patterns on your phone in seconds. Based on using weldneck flanges lubricated stud bolts with a 015 friction factor ansi 900 flange ansi 1500 flange ansi 2500 flange rec.

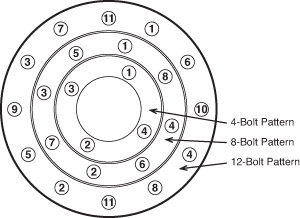

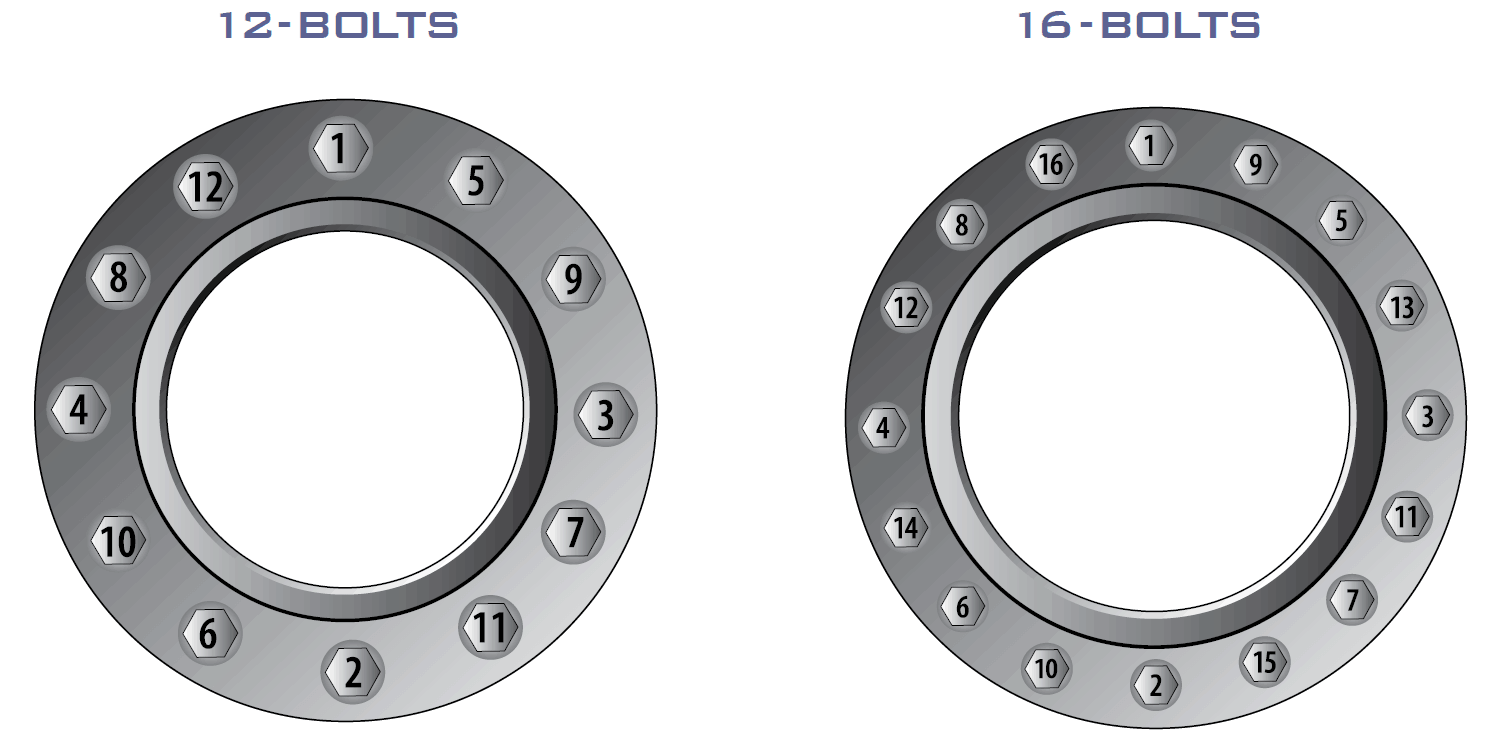

Class 150 Flanges Bolting Pattern Bolt Sizes ASME B165 All dimensions listed are given in inches. 2 Torque Increments for Legacy Cross-Pattern Tightening Using a Single Tool. AMG Bolting offer free guidelines for tightening bolt circles up to 96 bolts. 1 9 5 13 3 11 7 15 2 10 6 14 4 12 8 16. Check all bolts at 100 torque with a circular pattern.

Source: flangeboltchart.com

Source: flangeboltchart.com

The pattern itself is to apply to bolts 1-4 below in orderthen move to bolts 5-8 again applying torque in orderand. 1 33 25 17 9 5 13 21 29 3 35 27 19 11 7 15 23 31 2 34 26 18 10 6 14 22 30 4 36 28 20. 5585 hydro test pressure. 1 5 3 7 2 6 4 8 For 8 bolt flanges torque bolts in a criss-cross sequence. The app requires minimum storage space overall 2.

Source: rubberlining.org

Source: rubberlining.org

Just enter the flange size type and class and the tool instantly shows the ASME values for. The guide includes the tightening pattern for 16 20 24 28 32 36 40 44 48 52 60 76 and 96 bolts. Just enter the flange size class and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart along with wrench size. Garlock SEALING TECHNOLOGIES an EnPro Industries company. 1 5 3 7 2 6 4 8 For 8 bolt flanges torque bolts in a criss-cross sequence.

Source: paktechpoint.com

Source: paktechpoint.com

The table below shows torque sequence for flanges with 4 to 32 bolts. 5585 hydro test pressure. The table below shows torque sequence for flanges with 4 to 32 bolts. HYTORC offers the latest hydraulic bolting technology with unique patented benefits that provide industry-leading safety and accuracy. 1 9 5 13 3 11 7 15 2 10 6 14 4 12 8 16.

Source: uipintl.com

Source: uipintl.com

Set the torque wrench to 20 40 80 of final torque value and apply torque in a crisscross pattern. Nominal Pipe Size Diameter of Bolt Circle Diameter of Bolt Holes Number of Bolts Diameter of Bolts Length of Bolts1. 3 Example Legacy Pattern 12-Bolt Tightening Sequence. HYTORC offers the latest hydraulic bolting technology with unique patented benefits that provide industry-leading safety and accuracy. Ad We provide ANSI API and AWWA pipe flanges in carbon steel stainless steel alloys.

Source: repairservicecorp.com

Source: repairservicecorp.com

1 9 5 13 3 11 7 15 2 10 6 14 4 12 8 16. Just enter the flange size class and type and the app instantly populates the correct values from the flange bolt size chart and the flange torque sequence chart along with wrench size. Repeat until bolts have been successively tightened. Nominal Pipe Size Diameter of Bolt Circle Diameter of Bolt Holes Number of Bolts Diameter of Bolts Length of Bolts1. 1 5 3 7 2 6 4 8 For 8 bolt flanges torque bolts in a criss-cross sequence.

Source: quora.com

Source: quora.com

7 3 Recommended Tool Tightening Method and Load-Control Technique. Garlock SEALING TECHNOLOGIES an EnPro Industries company. Pipe Flange Bolt Torque Chart. Torque pattern for 36 bolt flanges. 1 49 41 33 25 17 9 5 13 21 29 37 45 53 3 51 43 35 27 19 11 7 15 23 31 39 47 55 2 50.

Source: blog.enerpac.com

Source: blog.enerpac.com

1 33 25 17 9 5 13 21 29 3 35 27 19 11 7 15 23 31 2 34 26 18 10 6 14 22 30 4 36 28 20. 7 4 Legacy Cross-Pattern Tightening Sequence and Bolt-Numbering System. 12 Bolt Flange Torque Pattern Author. 3 Example Legacy Pattern 12-Bolt Tightening Sequence. Length of studs 4.

Source: flangeboltchart.com

Source: flangeboltchart.com

Garlock SEALING TECHNOLOGIES an EnPro Industries company. 12 Bolt Flange Torque Pattern Author. 2 Torque Increments for Legacy Cross-Pattern Tightening Using a Single Tool. Garlock SEALING TECHNOLOGIES an EnPro Industries company. Repeat until bolts have been successively tightened.

Source: new-line.com

Source: new-line.com

7 3 Recommended Tool Tightening Method and Load-Control Technique. 2 Torque Increments for Legacy Cross-Pattern Tightening Using a Single Tool. 7 3 Recommended Tool Tightening Method and Load-Control Technique. HYTORC offers the latest hydraulic bolting technology with unique patented benefits that provide industry-leading safety and accuracy. 3 Example Legacy Pattern 12-Bolt Tightening Sequence.

Source: uipintl.com

Source: uipintl.com

2 Torque Increments for Legacy Cross-Pattern Tightening Using a Single Tool. The pattern itself is to apply to bolts 1-4 below in orderthen move to bolts 5-8 again applying torque in orderand. 3 Example Legacy Pattern 12-Bolt Tightening Sequence. Texas Flange has been in the business of prec. AMG Bolting offer free guidelines for tightening bolt circles up to 96 bolts.

Source: hardhatengineer.com

Source: hardhatengineer.com

15 Tables 1M Reference Values for Calculating Target Torque Values for Low-Alloy Steel. 3355 psi hydro test pressure. Even though flange blot toque calculation is possible they are normally selected from the pipe flange bolt torque chart. The pattern itself is to apply to bolts 1-4 below in orderthen move to bolts 5-8 again applying torque in orderand. Starting at the 1 bolt use the appropriate cross-pattern tightening sequence in the sketch below for.

Source: researchgate.net

Source: researchgate.net

All data is stored locally on your phone. Based on using weldneck flanges lubricated stud bolts with a 015 friction factor ansi 900 flange ansi 1500 flange ansi 2500 flange rec. Just enter the flange size type and class and the tool instantly shows the ASME values for. Check gap for uniformity. 7 3 Recommended Tool Tightening Method and Load-Control Technique Selection Based on Service Applications.

This site is an open community for users to submit their favorite wallpapers on the internet, all images or pictures in this website are for personal wallpaper use only, it is stricly prohibited to use this wallpaper for commercial purposes, if you are the author and find this image is shared without your permission, please kindly raise a DMCA report to Us.

If you find this site helpful, please support us by sharing this posts to your favorite social media accounts like Facebook, Instagram and so on or you can also bookmark this blog page with the title bolt flange torque pattern by using Ctrl + D for devices a laptop with a Windows operating system or Command + D for laptops with an Apple operating system. If you use a smartphone, you can also use the drawer menu of the browser you are using. Whether it’s a Windows, Mac, iOS or Android operating system, you will still be able to bookmark this website.